• Building a Nieuport 11 replica •

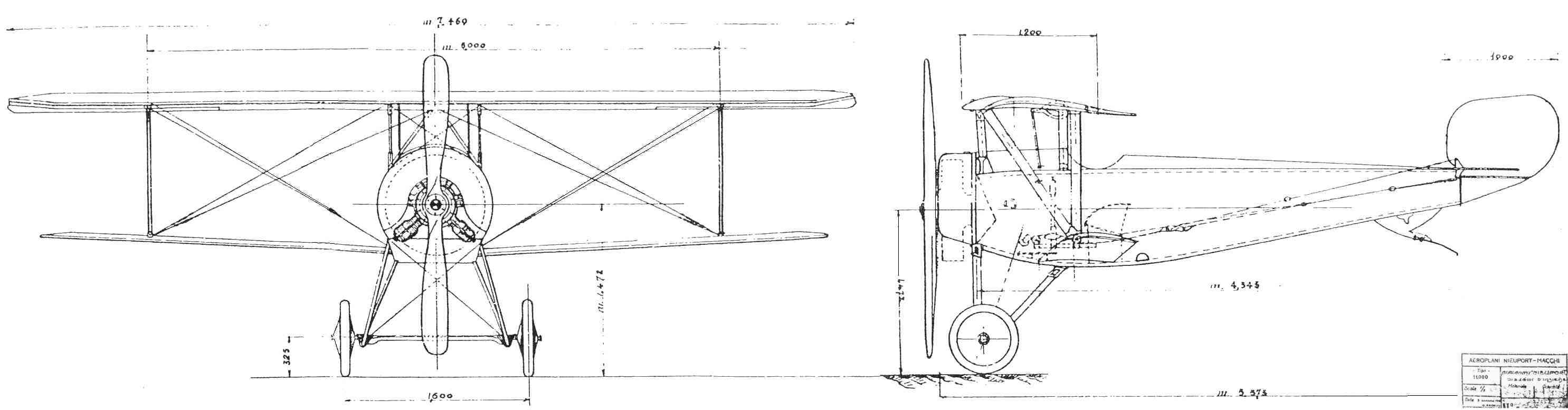

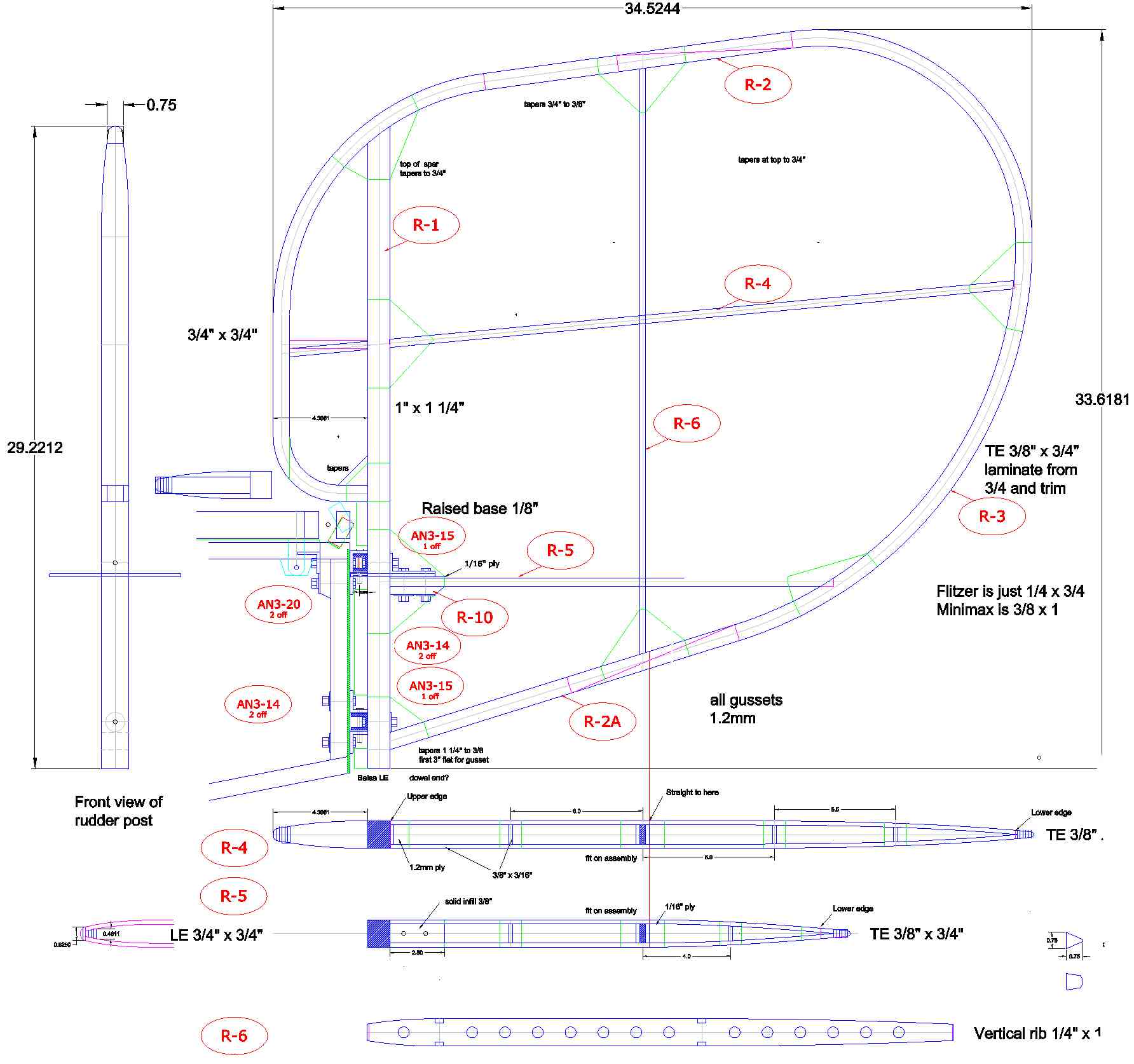

The rudder was produced as an exact scale reproduction of the original. (this is about 5% larger than the Graham Lee/Circa plans version. Builders using these plans have found the rudder to be too small and have enlarged it accordingly, bringing it to approximately true scale).

The shape is curved and consequently building in wood means steam bending and laminating the frame on a jig.

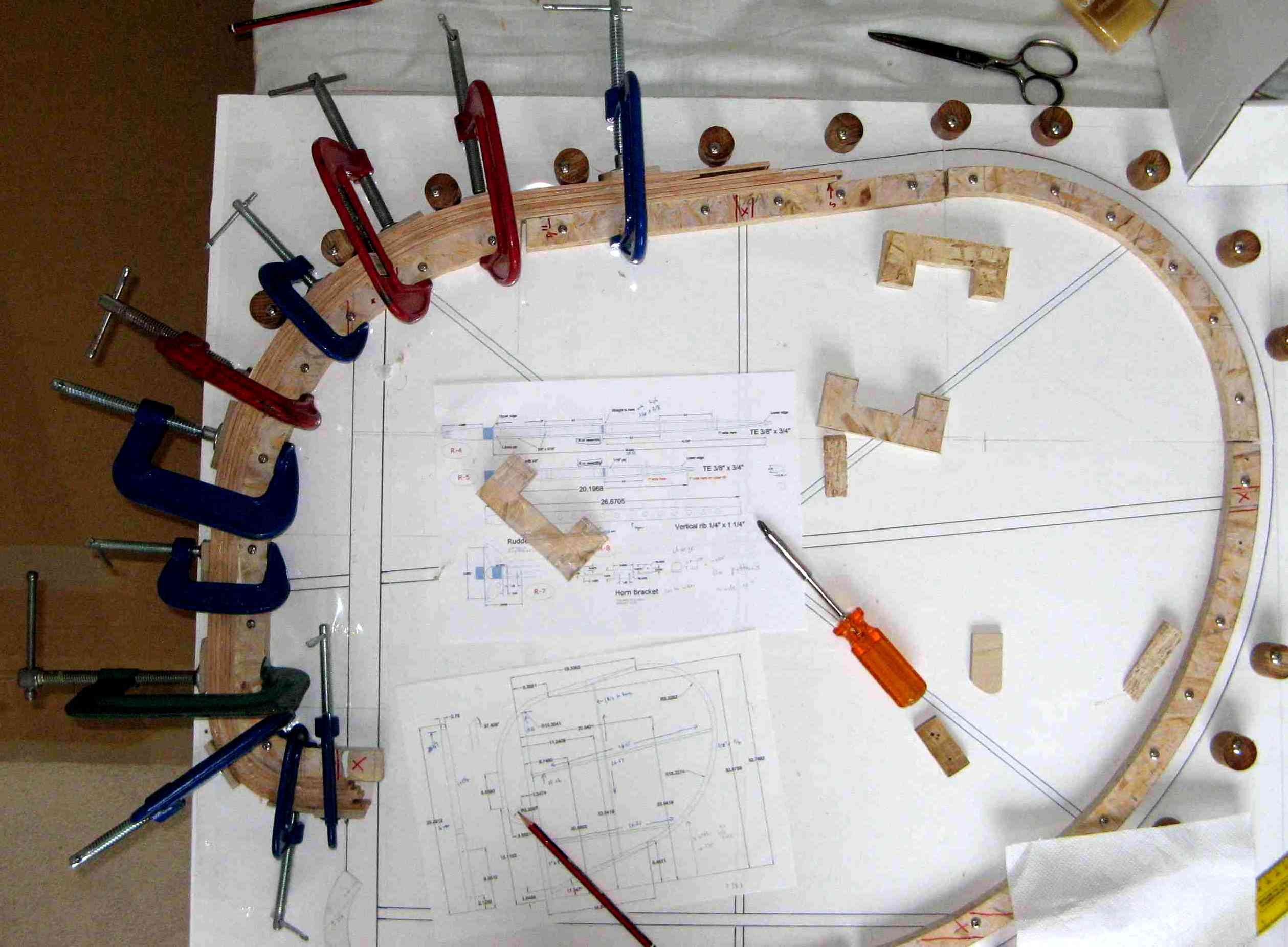

The first stage was to produce a jig around which the timber could be laminated.

A paper pattern was produced and attached to a sheet of 18mm MDF. Plastic film was then laid over the pattern to prevent damage to the pattern and to stop glue sticking to the paper.

MDF patterns were then made to the outline of the internal curve of the rudder frame and screwed to the base.

Cams were made by cutting an old broomstick into 1" sections and drilling an off-centre hole through each one.

Tightening the screw would thus push the cam against the laminations or release them accordingly.

A steam bender was constructed from an 110mm old water pipe with a standard cap at one end.

The other end was sealed with rags.

A wallpaper steamer was used to generate steam, with the steam plate removed and a valve plugged into the pipe.

A test piece was steamed first to calculate the time required and ensure the bend could be made without breaking the timber.

Strips 3/4" x 1/8" were steamed for about 20min and then bent around the frame.

The frame had to be built up out of three sections, and scarfed after laminating

Ideally you should allow for 'springback' as the timber will try to return to it's original shape. There are formulas for calculating this but in practice trial and error is the only solution.

I made no allowance for springback as after drying the timber strips would be laminated together and the glue would ensure the frame would hold its shape

The laminations were left in the jig for several days and allowed to dry. A dehumidifier was run to help dry the room.

The individual pieces were then separated and given several further days to dry out.

The laminations were then glued using Aerolite adhesive.

You never have enough clamps for this operation!

The frame was placed back in the jig and the ribs and gussets added.

The rudder post and main rib were drilled for the hinges and rudder horn and the completed assembly varnished.

Each component was weighed as it was completed to ensure it matched the calculated weight per the bill of materials.

The rudder horn and hinges were made from 6061-T6 aluminium sheet, angle and channel.

Each item was carefully sanded then sprayed with etch primer.

A final coat of grey primer was sprayed on to match the original aircraft colour.

The rudder will be controlled using two 3/32" cables, shackled to the rudder horn.

The rudder in place prior to covering.

All timber is coated with epoxy varnish.

The rudder will be controlled using two 3/32" cables, shackled to the rudder horn.